My thesis is about 3D printed connections, which is commissioned by Materialise. Materialise is a market leader in additive manufacturing. My purpose is to design, create and study different types of connections made by using Additive Manufacturing. Because this is a confidential thesis, I can’t give more information about the subject.

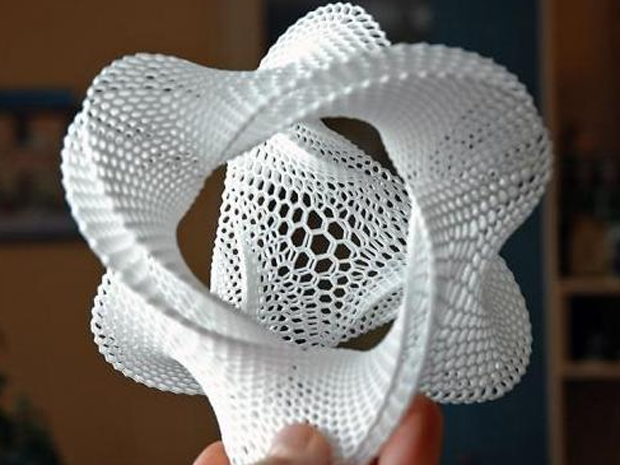

In this blog post I will explain the basics of additive manufacturing. With this method the work piece will be created by adding material , layer by layer. This is different than conventional methods where material will be removed by for example milling. This also creates waste. It is also different than injection molding where an expensive mold is needed.

Various techniques are available, the three most common are the following:

- Stereolithography (SLA)

http://manufacturing.materialise.com/stereolithography

- Selective Laser Sintering (SLS)

http://manufacturing.materialise.com/laser-sintering-0

- Fused Deposition Modeling (FDM)

http://manufacturing.materialise.com/fdm

If you want more information about the different techniques you can browse the websites by clicking on the links, or you can ask your question in a comment.